Spectacular wulfenite from Iran

In Iran, over 600 deposits and mining areas for lead-zinc is recognized that a few of them like Angouran mine are from those world biggest deposits of lead-zinc. However, it has not been reported yet any deposits of lead and zinc together with molybdenum in Carbonate rocks. Most resources for molybdenum in this country are associated with those deposits known for copper. In the mining region of Kuhbonan-Bahabad in Yazd province, there are many deposits of lead-zinc that the number of these deposits are over 40. Most of these deposits were active long time ago with no determined date.

When people are going to these mines and see how professionally the tunnels are dig with simple tools at that time, we came to this point that even the miners at that time have no advanced knowledge as we do have now they had enough skills and practicality to dig as far as we do now with most advance machines and tools.

By seeing these deposits and the many tunnels and shafts they had dig through the mountains, we basically came to this conclusion that those guys put a lot of time to reach the places where they could found ore in there without even we notice they have manipulated the nature around when we are just several meters away the mining location. Mostly, they have stored their ore waste in the same tunnels after they had dig and took out the ore out. For now, that we are going to search for lead minerals like Wulfenite, it is very hard to move around and sometimes we wish they could have took them outside of the tunnels so that we did not have to move their ore waste once again. Anyway, most of these deposits mainly are located in Carbonate sedimentary rocks (Dolomite and limestone) which are related to Upper Paleozoic, Triassic and Cretaceous. Studying these deposits has shown us that existence of non-sulfide mineralization including Carbonate and zinc silicate and lead carbonate in these deposits is one of the main features of them. The Ahmad Abad mine is one of the non-sulfide deposits is in this region that is located in 80 Km of north east of Bafq city and in 5 Km of the Ahmad Abad Village in Bahabad County. Geographical coordinate for this mine is 55o 53’ 30’’ to 55o 54’ 30’’ E and 31o 57’00’’ to 31o 58’ 15’’ N.

This mine first was under mining operation to extract lead back in time from at least 150 to 180 years ago. The exact time and duration is not precisely determined in history. However, from the history of Qajar dynasty who ruled out the Persian lands from 1785 to 1925 we know that the Army was supported with lead extracted from this mine to fight against the Army of Tsarist Russia. In one of one of the historical documents belong to that time, the commander of Iranian Army in letter wrote to the governor asked for more lead as they needed more to make them able to use in their weapon and armament. In this letter he asked for more lead to come out of Ahmad Abad mine which probably show that there were not many deposits of lead available at that time since he pointed and named just this mine. He asked for urgent help since they were about to lose the war to the Army of Tsarist Russia. Anyway, from what we know now from history, they lost the war and gave up a part of their lands to them. From what we see now in tunnels and at the location of the mine, it seems that the miners at that time did their best to support the Army to make a victory but the war did not went in a way they wished for. Totally, there are 8 tunnels at the location of the mine and not all belong to that time. Most of them are belong to that time but a few were dig around 40-50 years ago with the purpose of extracting the remaining lead at the location and also zinc. In the past two decades some researching activities done at the place for zinc and possibility of other kind of ore. It seems in none of the periods of mining till the latest activities occurred in the past two decades, people had no recognition of molybdenum and its mineralization. The first identification for Wulfenite at this locality was reported 13 years ago.

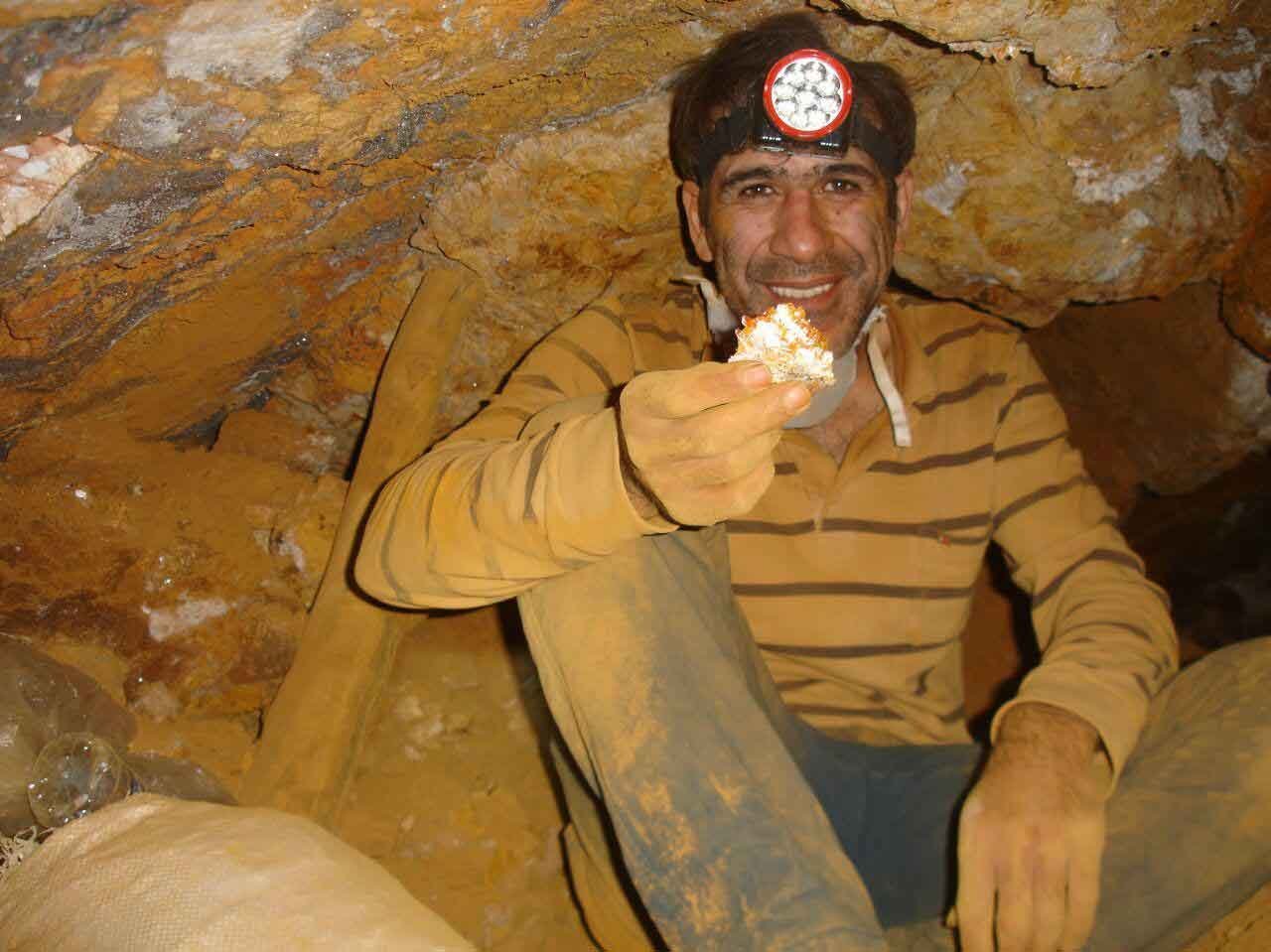

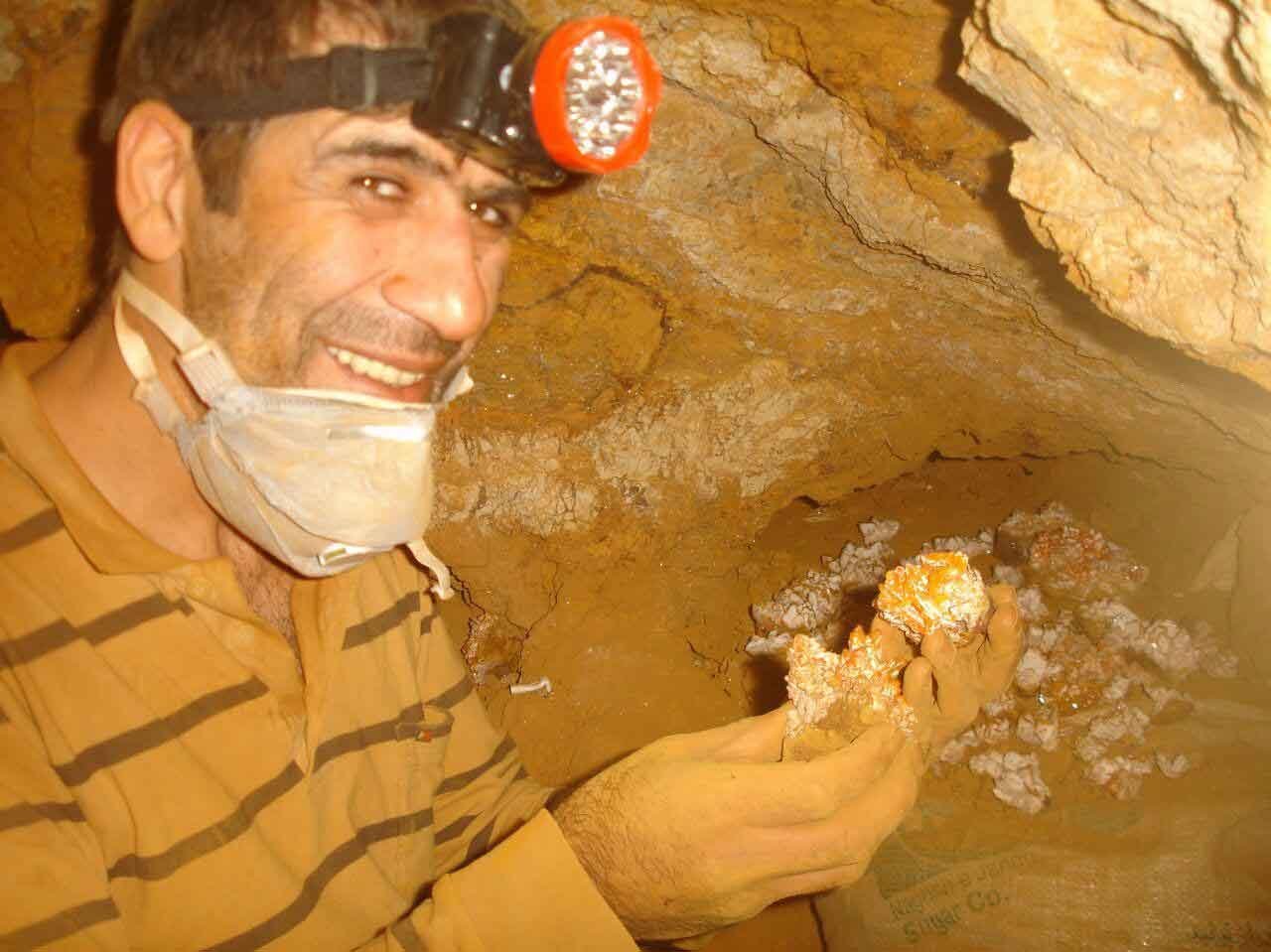

Mineral diggers in Iran, after just having heard about the signs for Wulfenite specimens went there to check if this mine is a new potentiality to find pockets of Wulfenite samples. When the first group went to the location of this mine as usual try to first check the ore waste outside of the mine to see if the report was true and if they would find some even if they are broken among the ore waste and how they look like. The team first did not have enough information about the place of the mine just knew that it is in 5 Km of Ahmad Abad mine and they had no contact with the authors and researchers of the article and they were not willing to do so because naturally most of the mineral diggers want to work out of others sight, kind of secretly especially in this case that it could became a new locality for Wulfenite samples. Usually, as what mineral diggers in Iran say, researchers and explorers whose purposes are ore and not finding crystalized minerals samples, do not search all over the mines carefully and always there are possibilities to find crystalized minerals samples in case they did not have any reports on them. In the case of this mine that those researchers announce there are some signs of existing crystalized wulfenite samples, the team who first got in there was very hopeful to find major pieces at the location of the mine by searching more carefully the tunnels and by searching all tunnels till the end although the signs of what researchers were talking about was not really considerable in our world of mineral market. Very tiny crystals of Wulfenite is not interesting for collectors and dealers but it is interesting for mineral diggers, since they know there is always this big chance to find better and better pieces it is just a matter of time, hardworking and accepting the risks and dangers what usually those researchers never consider.

Since the mine is located in a region that there are more other deposits, the team first needed to get to the Village of Ahmad Abad which was as close as 5 km of the mine as it was mentioned in the article. Usually for such abandoned mines if it is not so long people have left it abandoned, there should be people in the village who have heard and probably seen the place before. Usually such villages that is as this close to the mining location, the major career of the village’s men should be mining while mine were or is active. Since the last time that this mine was under mining operation was 40-50 years ago and in the case of the first time the team attempted to get there it was about 27 years ago, the team was optimistic about finding people in the village who had worked there so they could use the miners guides while they want to search the tunnels. It is always dangerous to search the tunnels of abandoned mines especially in this case that the tunnels go in different direction and were dig far than the team though at first place. When the team got to the village and asked for people who had worked in the mine at that time, they surprisingly found out that all the miners had already passed away and their family thought that the reason of dying at younger ages than what the team expected before is because of working in that mine. Their families said that most of them died due to respiratory diseases probably lung cancer. There was a guy who knew the mine and his father was working there. He described a very interesting story back in time when the mine was for the last time active. He talked about a German guy which seemed he was a mineral collector or kind of dealer! He said that his father sometimes brought home some pieces of rocks from the mine which they were colorful and as what he described like “decorated cookies”. He said that his father for two times met that German guy to give him those rocks to earn some money to make a better life since the salary for working at the mine was not good enough for his family to survive in as what he said “ in a dry desert ”. He described that the German guy brought with himself a big suitcase full of cotton to put the rocks in that suitcase. We know at that times lots of American, French, German and Russian geologists and mining engineers coming on and off to this country as experts for guidance. By hearing that, the team guessed that the mine should produce some major samples.

The people of the village also call that mine Bon-e-Anar which means the root for pomegranate tree and this was the name of the place over 200 years ago. They said in the past they call it Bon-e-Anar because there were a huge tree of Pomegranate at the top of the mountain where the mine is now located. They said that now there is no sign of that tree. People used to go there because they considered the tree as the tree of dreams and wishes. They narrated from their ancestors that a few people from outside of the village one night went to the location of the tree and destroyed the tree. They said back in time about 200 years ago when for the first time that mine went under mining operation after a while that those men of the village working there and got sick and some died, people of the village thought that the reason was due to the Anger of the tree. They were saying that those men of the village that went working in the mine were destroying the root of the tree by working there. They thought that root of that huge tree was all over the mountain and so when their men going there and dig in tunnels they actually were trying to destroy the tree. So, they stop working there and so because of that governors of the region who needed them work there decided to destroy the tree and thought in this way the men of the village would back to the mine and work. By doing this, certainly the people of the village got angry because somehow they respected the tree. Anyhow, probably the governors found a way to get them back to work but there is no evidence concerning this and even now the people of the village do not know what really happened after.

After receiving such exciting news and spending one rainy night with villagers, the team headed toward the mine. Finding the way to the mine was easier than what expected before, but the time when the team headed toward the mine was winter and as the last night was heavily rainy some parts of the road were destroyed and the team needed to get off the car to mend the road or to find new way and that made the time getting to the place later than what expected. At the mine location there were not much ore waste outside and what was already there seemed belonged to activities for explorations done in the past two decades for zinc. The ore waste from other tunnels which were worked earlier were left in the same tunnels and they did not bring them out. There were a few man made houses that looked like they were built also around 50 years ago. They might be used for resting purposes but not living. Good to have them for the team to put their equipment and other stuffs in there. The team left the village at 6 am and although the mine is so close to the village but by considering the hardships they went through they got to the mine location around 10 am. The first task was to find all 8 tunnels as it was reported. That was hell of a job. It took almost 3 hours to find all. Most of the tunnels that were dig have very small entrance some were closed which showed even the researchers who reported all this even did not went through those tunnels. It was both a good and bad news for the team. It was good since they thought that not having search all tunnels shows there is still some great potentiality for this locale that was hidden at least for several years after those entrances got closed. The bad news was the risks and dangers that such tunnels always have. Previous experiences showed that such tunnels always have this risk that even if you are walking through there is some kind of risk of collapsing the roof above. Besides that, opening and cleaning is another big thing to do. Four of the eight tunnels were closed. So, for the first try we forgot about those were closed. Two of those four that were already had opened entrance were belong to latest mining operations. As the way they were dig like bigger entrance and having some safety stuffs around and also checking them out proved this fact. One of these two newer tunnels were belong to activates done around 20 years ago and the other one belong to 40-50 years ago. The younger tunnel was dig for zinc and not much far. Nothing interesting found there. The team continued the same day to check the other tunnel which were belong to 40-50 years ago which dig for lead. That tunnel which is uppermost tunnel of the mine was totally large with many branches inside. Also the team for several time confronted Porcupine (Animal) living in mines tunnels. They were big, disgusting and dangerous. Their quill tips get lodged into the skin and are difficult and painful to remove. While they were searching the tunnel at the very first hours, they noticed a small hole to the wall of the tunnel with many cracks around. Breaking the cracks popped up quite a big pocket of yellow colored Wulfenite with association of white funny crystals of Calcite. It was totally cool to find such pocket at the first day attempt especially that easy and fast although it was the only easy and fast experience of finding pockets at that mine but the rest up to now were the hardest and most challenging in whole career of the whole team. After finding that first pocket, team decided to leave the place and the next day attempt to recover pieces from the pocket. It was already late to left the mine. By the time team left the tunnel, it was around 9 pm. Very long day and all were tired to hell but thinking about the first pocket they hit at the first day of attempt was a refreshing thing. All members thought that they would be able to find other pockets as easy as this one but it never happened as such easy up to now. The next two days was spent to open the pocket and recover the pieces. After the first hit the team left to home and decided to get back with more equipment and tools to spend more days or better say weeks there.

Mineral diggers in this country have many problems to search and explore in mining regions. Some mining parts are heavily under security controls and some others are under environmental protection and those security guys if ran into you and you have not yet got the license for your presence in the region, you will be in huge trouble. Getting a license is also another big deal. Most of the time you would rejected and if in any case you successfully got one, probably you had invested unreasonable amount of money and also spent or better say waste a lot of time.

Anyhow, for a new location, mineral diggers prefer not to go through the procedure of getting a license. They usually want to first make sure the location worth the whole procedure then they will go through.

In the case of Ahmad Abad mine, after the team hit the first pocket successfully, but they still decided not to apply for the license. The reason was due to keeping all these secret till they hit all the other pockets that are as easy as the previous one although for the next times they had to apply for the license to get there. Because both the villagers and also security patrols made them to do so. Villagers no matter where you are going in this country, if they see some strangers coming with off-road vehicles with digging stuff, they thought that probably there should be some sort of treasures out there near their village. So, first they try to get a share but when they see mineral diggers disclaim everything, they inform governors so the real problems will start. Mineral diggers disclaim any treasure in shape of ancient and archeological stuff like coins, bowl and plates, but they know they are looking for real treasures which are minerals.

The next mining project almost took three weeks, non-stop working. The team opened all the other tunnels entrance and started exploring them for minerals but with no good shot. Most of the findings were in middle quality or lower and pockets were too small.

The four tunnels which had closed entrance at first place are of the most risky places that any of the team members have already experienced. It seems all of these 4 tunnels are the oldest ones. This mine is located on one of the most seismic region of the country. Many earthquakes occur in this region and probably this is the reason that the mine is not safe enough to work with less concerns and many roofs had already collapsed and other from time to time collapsing while the team is working. All the team member never used or will use mining helmet or any other safety hard hats because in the case of this mine, using that can actually cause harms. As it is mentioned before, roofs above the team can collapse at any time due to hammering or mallet the walls for digging or sneezing due to dusty weather of the mine, or by a bad chance of being at mine while the earth shakes. The first thing that warns the guy inside the mine just a few second before collapsing occur is feeling the falling of soil and dust on your head. By experience, wearing a hard hat will not let you know if any collapsing will occur. The first time when the team attempted to explore one of the tunnel which its entrance was just opened, a disaster was about to happen. One of the guys who was crawling on his knees in front of others after finding the way through other branch of the tunnel that goes upward to other direction got trapped. The way to the other direction was crazy still cannot believe that in past times our ancestor should go through all these for several times and took the ore out of these ways. It is unbelievable! There was not enough room in the passage for moving around and guys needed to move on their knees with bended head and at some parts just crawling to pass through. The guys behind suggested the guy moving in front to remove his helmet since it was making movement harder. The front guy denied but others did. A few meters a head of them, the guy behind when watching the other guy noticed that from the roof soil and dust was pouring on his helmet and he did not noticed, so stopped to warn him and get back but for the guy in front was too late. He was already under the collapsing roof. What he saw in front was nothing just dust all over his friend. The other guy behind him also felt the pouring soil on his head. There was not space for turning just had to move backward in the same position before other roofs collapse on them too. They backed to the previous tunnel and out of that passage, they just got worried about the guy trapped. Is he alive? Whether he could drag himself toward in a safer place? How can they get to his place for help? Are there any other way from other tunnels to his place? Such questions would always arise in this situation. However, since they were new to the mine and did not know other ways they decided to go through the same way and clean all the mess up to reach his place. Luckily, nothing heavily collapsed by which moving and breaking it make rescuing him harder. Also the guy was lucky because nothing heavy felt on him so that he could drag himself toward although he got injured. After cleaning all the mess up which took about 3 to 4 hours, and reaching to the other side of the way where there is quite bigger room to move around and two other way ended to that place by which it make breathing easier, they found the guy relaxing on rocks and smoke a broken cigarette. Smoking in such areas is of those crazy stuff most of them do. For newbies to the mine, seeing cigarette stub should mean they are safe since some other guys been there smoked many and left the place so there is enough oxygen to breath and also there should be way outside!

This story and a few others that mostly happen in these tunnels convinced all to never put on any hard hat and actually this caused many survives. A lot of time happened that guys felt pouring soil on their head and ran away in seconds and after that collapsing occurred.

Besides the risks of collapsing, what makes working there hard in the climate of the mine. It is too dusty and always your skin get dirty with dust and limonite which makes sweating the absorbed limonite even after a week left the mine. All members are using respirators, but really not any of the different kinds of respirators they have used so far worked well enough. Sometime while working breathing with them in dusty situation is much harder and sometimes they had to remove them for while maybe minutes to receive more oxygen. They have also used expensive and modern respirators with special and expensive filters that will not let dust through but the problem with them in this mine is that the filters could not resist till one hour. Seems they absorb all the dust around and do not leave any space for air and oxygen to come through.

The team always use simple tools for digging and it is not possible to bring heavy machinery tools inside most of the tunnels. The ways to the potential parts of the mine is usually not appropriate for bringing tools that are not considered small. All kind of small hammers and hand drills are usually apply for exploring. The walls are not hard and usually with this stuff the job can be done. Also, the condition of the mine is not appropriate for hard strikes and impacts since the mine is always ready to collapse and bury the body inside. Most of hard situation the team went through was due to the strikes they had to put for opening the pockets. Generally, while they are in the tunnels whether they are working and striking or just walking around, they are always thinking of the time they walk out of the mine, see the sky and breath fresh air, however, sometimes there is this feeling that it might not happen and it raising our concerns.

From 2003 that the very first samples had found up to now, the team had almost every year two or at some points more mining projects there, but the major pockets hit are not exceeded over three and maybe with more quality standards just one! Recently, it is also getting harder to find new possible potential part at the mine. There are still some parts that lots of pockets of them remained but most of them are aggregated in a way that it is most looks like ore instead of crystalized mineral and also some other have drowned in a sea of Calcite and Calcites are like cement around Wulfenites and for some over time it looks like the Wulfenite thing is dissolved in calcite. The last shot for finding new pockets was very risky and felt all like they are close to death. In the most potential part, the team did the most risky job ever. After finishing exploring that region, members decided to start a new exploring from the other side and try to reach the place. There was a tunnel behind as well and it was searched before. It ended to quite a big room full of ore waste by which it was fulfilled by miners in the past, probably around 200 years ago or so. Team members found some old mining lights which archeologically they are belong to about two century ago. These mining lights are now kept in the museum of Geological Center of Iran and also one in the museum of Bahabad Natural Resources. The problem to get to other side of the potential part that we guess probably still there is at least one pocket there was the room full of ore waste, tones of them. In the ore waste, there were several samples of Wulfenite, broken ones, which shows that miners at that time saw and probably know the beauty in them. They are sure that even in the past two century ago, people understood the beauty of them because surprisingly, one very beautiful sample was placed at the other side of the room next to one of the mining lights. It totally looked like somebody with care had put it there. They are sure that not even in the past half century ago anybody went there because all the ways through that room were all closed and the team had them opened first. Also the amount of dust that were on the sample was much and for sure it took more time than at least half century when that amount of dust came over the sample. Concerning the ore waste, it was impossible to move some of them it seemed that over time the roof had settled and subsided onto the ore waste. By removing some it was likely the whole ore waste and the roof above fall on members. Tried several times but each time had to put them back and make things fix. All the team members had a lot of brainstorming regarding how it is possible to go over the room, they could not even make tunnel from sides because it could cause collapsing all those ore waste and close the way back. While thinking about this outside of the mine, all the members suggest crazy and somehow bravery solutions but as soon as got to the place see and feel things close to the place where should all those crazy suggestions perform, suddenly no body were volunteer to do so. What all came to conclusion was to make some sort of barriers and make intentional collapse by striking to the ore waste, leaving the place immediately and come back to place later to see what are the new options. This should be done only with two guys. They set up all the barriers and improved the escape ways. All the necessary things that they had to do to have the best possible safe subversion in the mine got ready. However, after having done the subversion, the amount of ore waste coming was out of mind. The guys inside barely could survive and after all the other members went back there after hours, they noticed that a lot of roofs nearby also collapsed and the volume of ore waste was much more than what they expected. So, not even that potential part is now all ruined, but also the main passage and other branches of the tunnel around that place are under ruins which make it almost impossible to clean and open it again and guess no one else could do so. Also, for sure if there was any other pockets there, now it is damaged.

It seems finding new potential part is way too impossible and working on other previous parts will give nothing special. Anyway, our team will never be disappointed at any location although it seems for this one it is much harder to start another mining projects there.

An article of this famous find was published at the german mineral magazine “Mineralienwelt” in 2015.